On December 1, 1913, a transformative event in industrial history took place: the introduction of the first continuous assembly line by the Ford Motor Company in Highland Park, Michigan. This groundbreaking innovation, designed to mass-produce the Model T automobile, forever altered the landscape of manufacturing, shaping industries and economies worldwide.

A New Era of Manufacturing

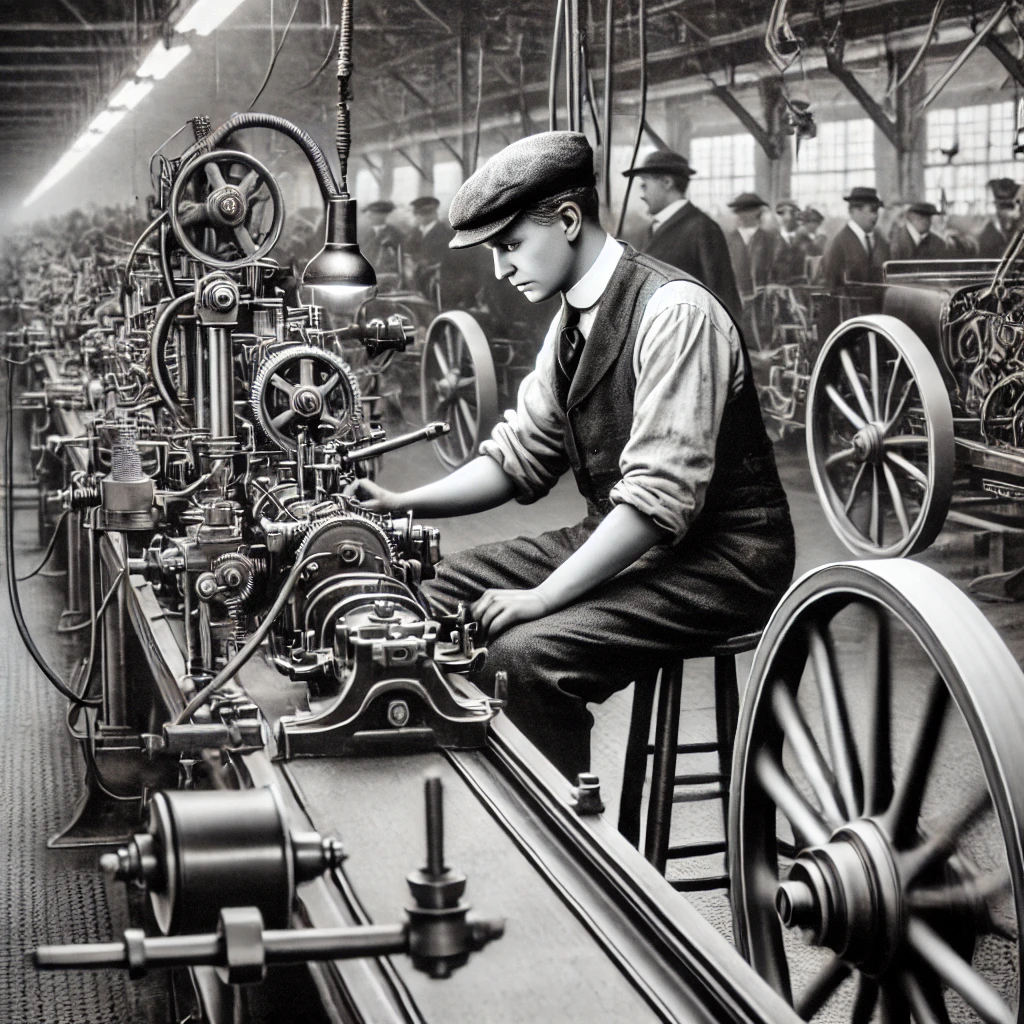

The continuous assembly line, conceptualized and implemented by Ford engineers, was revolutionary in its simplicity and efficiency. Unlike traditional methods, where workers crafted entire products individually or in small groups, the assembly line divided production into specialized tasks. Conveyor belts moved car parts down the line, allowing workers to remain stationary and perform repetitive tasks with precision. This method drastically reduced the time required to produce a single Model T from over 12 hours to just 93 minutes.

The implications were profound: mass production could now be achieved on an unprecedented scale. Ford’s innovation not only allowed the company to meet growing demand but also lowered production costs, making automobiles more affordable for the average consumer.

Significance in Historical Context

The introduction of the continuous assembly line coincided with the rise of industrialization in the early 20th century. At the time, manufacturing was undergoing significant changes, but Ford’s assembly line marked a critical turning point. By optimizing efficiency and standardizing processes, it set a model for other industries to follow, from consumer goods to heavy machinery.

Moreover, the assembly line redefined labor. While it created new jobs, the repetitive nature of tasks led to debates about worker satisfaction and the monotony of industrial work. In response, Ford made another bold move in 1914 by introducing the $5 workday—doubling the typical wage—to attract and retain employees. This not only improved worker conditions but also created a cycle where employees could afford the very products they helped build, fueling economic growth.

The Legacy of the Assembly Line

The principles of the continuous assembly line remain foundational to modern manufacturing. From smartphones to airplanes, industries worldwide rely on streamlined processes inspired by Ford’s innovation. Technological advancements, including robotics and artificial intelligence, have enhanced the efficiency and precision of assembly lines, but the core concept remains unchanged.

Beyond manufacturing, the assembly line has influenced fields like healthcare, logistics, and software development, demonstrating its versatility. It also laid the groundwork for consumer culture by enabling the mass production of goods at accessible prices, shaping lifestyles and economies across the globe.

Today, the legacy of Ford’s assembly line is evident not only in the products we use but also in the principles of efficiency and scalability that drive innovation in every sector. Over a century later, December 1, 1913, stands as a testament to the transformative power of human ingenuity and its lasting impact on our modern world.